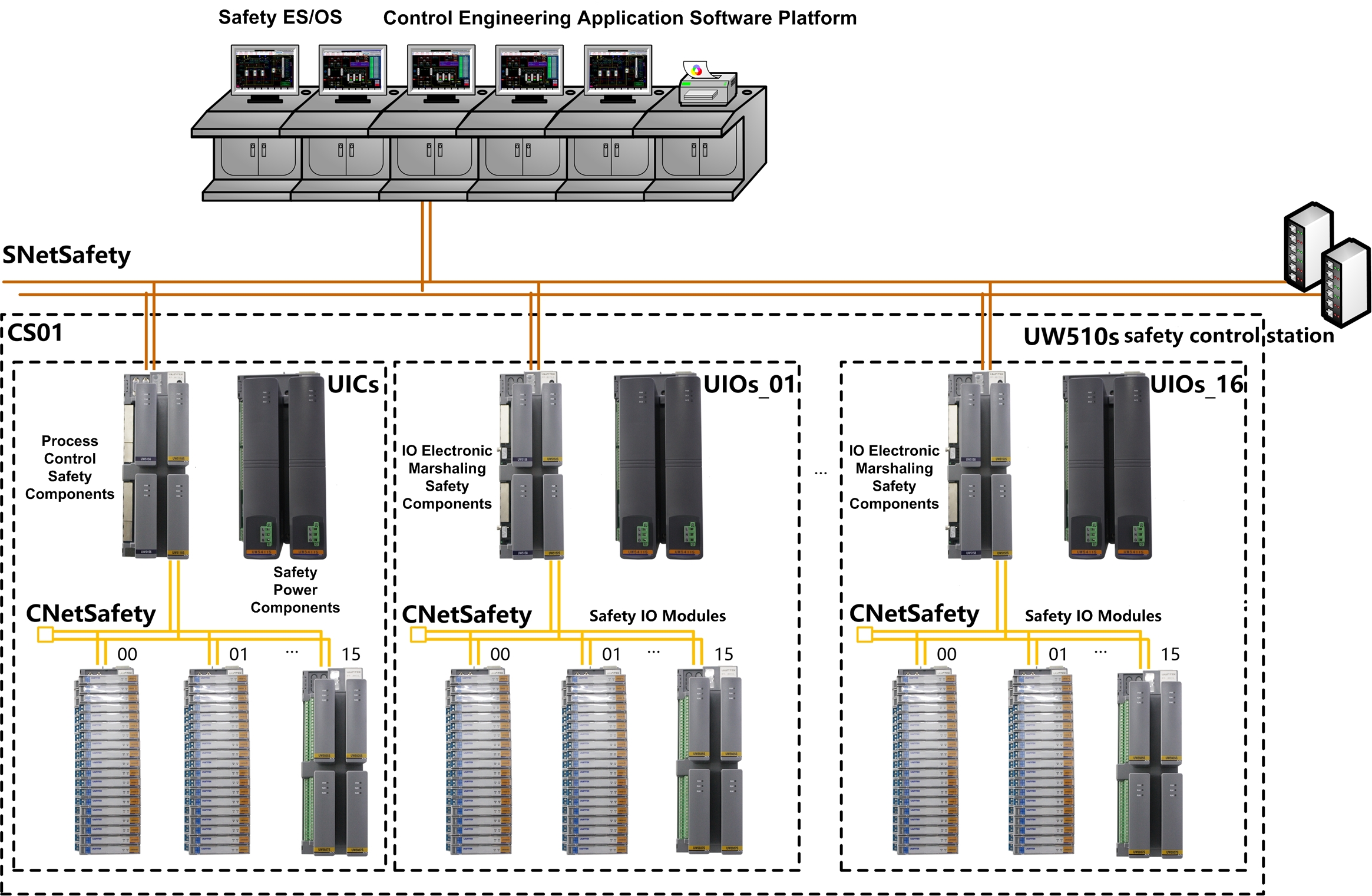

UW5100 Electronic Marshalling

The electronic wiring system is a new generation process control system that integrates software defined data link technology, software defined I/O technology, and optical communication replacement cable technology on the basis of existing DCS, achieving technological innovation and construction.

Software defined data link: Separate control module and I/O module, based on network technology and software defined technology, change the traditional static fixed connection mode between control module and I/O module, and achieve dynamic redistribution of data link;

Software definition of IO signal types: Software configuration enables input and output of multiple signals, achieving single channel signal isolation, type configuration, programmable amplification, data processing, fault diagnosis, filtering,linear correction, engineering conversion, etc., supporting online module replacement and signal type change without opening the box;

Optical communication replaces cable connection: The I/O module is located in front of the industrial site, where it is located. It achieves digital to analog and analog-to-digital conversion at the signal end, using advanced industrial AON optical network and TUV certified functional security protocol. Compared to civilian PON technology, it has leading communication fault tolerance and security, as well as high anti-interference and environmental adaptability.